I don't sew with cotton knits very often, readers. Here's why:

First, it's hard to find high-quality, stable, cotton knit fabric -- the kind you find in your run-of-the-mill American Apparel, Russell Athletic, or Jockey T shirts. Instead, what I always find are super-stretchy, thin-bordering-on-transparent knits. Or polyester ponte.

Second, men's ready-to-wear knit shirts are so easy to come by that it really doesn't pay to make them myself. And it's not easy to get a professional finish without a coverstitch machine. Plus, even if it comes out perfect, all I've made is a T shirt.

That said, I do enjoy a challenge, so today I decided to try my hand at making a knit shirt with a woven placket and bias trim along the neckline in place of a collar.

My fabric is something I picked up a few months ago from Mood.

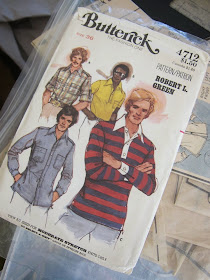

I worked from Butterick 4712 (up top), and used the front placket pattern piece (from View B & C, both knit shirts) but eliminated the extension that becomes the neck facing.

I did a lot of sample stitching (on a similar knit swatch) on my Brother 1034D serger till my seams looked good.

|

| Sleeve and hem trim. |

My first problem occurred when I mistakenly attached the front left shoulder to the back right shoulder (or was it the other way around?).

I realized this only after I had attached one of the sleeves. The result (below) is a mess. The short sleeve is attached to the armhole of the back piece and the neckline of the front piece. Eek!

At this point, I was ready to throw in the towel but, since I have plenty more of this blue knit fabric, I decided to treat this like a muslin and see whether I could salvage it. I trimmed off my serged seams, separated all my main pieces and stitched them together again (correctly this time). Unfortunately, all this handling stretched the fabric out and the seam allowances didn't always match.

I made my placket out of a piece of sturdy woven tan cotton left over from my recent dress pants project. I cut a bias strip from the same fabric for the neckline.

On my first try-on, the neckline looked stretched out. Yuck.

I dampened the fabric and pressed it again to shrink the neckline a bit, and the result is almost wearable. If I leave the left side flopping open it looks reasonably normal.

Next, I threw the shirt in the laundry and machine dried it. I also added a button to the placket.

On Michael, who is considerably wider in the shoulder area, it actually looks pretty good. He wants it, so I'm giving it to him.

I would like to try this again. Next time, I won't handle the fabric so much, I'll stay-stitch the collar, and I'll make sure I add the front placket before attaching the front piece to the back. Adding the placket when I did, when the shirt was all sewn together, forced me to stretch the fabric too much. I could probably also have stretched my bias strip -- but not my knit fabric -- more as I stitched it to the neckline. Anything I missed?

It's not easy to make a shirt that combines knit and woven fabric: they have such a different hand and knits -- this knit in particular -- are stretchy. Maybe I need to search for a knit that's thicker and more stable, if I can find one.

In conclusion, not a disaster but not what I'd hoped for either. Live and learn.

Have a great day, everybody!

I've done that same thing on shoulder seams before...on something that seems easy, your mind can wander. The end product looks good, though!

ReplyDeleteBias trim on a knit shirt requires that you not stitch one to one. Especially on the front, hold the trim/finishing bias under some tension to ease in some of the inevitable stretching of the neckline.

ReplyDeleteOh dear, this is not helping my knit phobia.

DeleteHow about buying a 3x RTW knit shirt to get the fabric you want, then cutting the pieces out of that to make the shirt you want (i.e. special placket)

ReplyDeleteI think about doing this all the time, but have never actually tried it. I also have a hard time finding knits worth spending my time sewing.

DeleteI do this all the time! Just remember to shrink it first... or you'll have a crop top like I did.

DeleteI may be a terrible person, but I was kind of happy to see your sleeve attached to the collar. I did the same thing last night. At least I had my shoulder seams correct. Regardless, your shirt looks great.

ReplyDeletewhat you want is an interlock knit. They're thicker and more stable than most jersey.

ReplyDeleteI've been thinking about a knit shirt with a woven placket and collar myself... But I wouldn't swap out the collar for bias binding. The pattern piece for a collar or stand has a 'set' size and shape to which you can then attach the stretch-happy jersey neckline. In my opinion, replacing that with an equally-but-differently happy-to-stretch bias strip is asking for trouble.

ReplyDeleteGreat post (as always), thanks! Pre-washing the fabric might help too?

ReplyDeletebrave you - i cheat and would use vilene strips at the neckline to keep it stable (but i also dont have a serger) - great rescue..... and great shirt - nice mix

ReplyDeleteNot bad at all considering all the trouble getting there. :-/ I bought a similar new pattern last week for men and boys,Simplicity 1286, with the idea of making some shirts for my boys. I'm excited to see your next creation in the style. Any tips about sewing together the knit with the woven?

ReplyDeleteI take a different approach with combining wovens and knits. I make the woven a decorative element ONLY, and give stability with an interfaced facing. Works well for me.

ReplyDeletePeter you should do a post on: When to make it or buy it. My sewing decision often are based on price and time. For example, I rarely make a shirt unless it's something unusual, or something historical I want to recreate. Sometimes it's to make a liberty of london style shirt for a fraction of the cost. RTW is so cheap and available that it doesn't make sense to make it. Other considerations are for just sheer pleasure. I generally focus on sportswear in fabrics, colors that you traditionally don't find in menswear. This make the project unique and different. I also sew to "knock off" high end RTW looks depending on what I see on the runway. When I can make the same thing for under 200 bucks versus 1000-2000 for a designer menswear suit, then I am all in.

ReplyDeleteI would like to others thoughts on when to make it versus when to just buy it.

That's an excellent suggestion. Thanks!

DeleteCorey, Im so in your camp. Sewing has given me the chance to have something totally unique, so I'm not interested in making something that I can buy for 4 or 5 dollars on a clearance rack at Kohls.

DeleteHad these thoughts in Uniqlo this week on holiday. One, I hate buying clothes. Two, all that work and you have....a tshirt. And they have much nicer fabrics (having a little petting party with this tshirt.....).

DeleteThat said, prewash, and starch it up to stabilize. Sew with tissue paper in the seams you aren't using clear elastic in. Melissa Fehr /Fehr Trade has a lot of smarts about knit sewing, so does Steph C of Cake.

And luck.

I can't imagine a neckline binding in a woven, doing it in a knit is hard enough. The binding needs to be smaller than the length of the neckline yet able to stretch to fit.. I always refer to this video: http://www.dailymotion.com/video/xwvobk_a-neckline-binding-for-knits_lifestyle

ReplyDeleteI agree that a neckline binding in a knit would have been easier and hug the neckline better than a woven. I've tried the woven binding before and won't do it again.

DeleteWilly!!!

ReplyDeleteI also wonder if the woven bias will be rough on tender back neck skin- my son and husband are super sensitive though, so I may be paranoid :)

ReplyDeleteImho, I think the shirt turned out very well. And I learned a new fabric today: ponte. Thank you.

ReplyDeleteIn shopping for tees or other knit shirts, I actively seek the thinner, more transparent fabrics (like underwear or even thinner), then layer. I'm also a big fan of the 95% cotton/5% Spandex shirts that both stretch and conform. The fabric often has a slight sheen that 100% cotton doesn't, which I consider another advantage.

The rugby-style, cotton/woven shirts I see in the stores are almost always the heavier cotton, heavily dyed, and turn stiff after the first washing. Uncomfortable, rarely in my size, requires ironing, heavy, and not very flattering.

I agree that you might want an interlock fabric. I know you generally shop the garment district, but fabric.com has a really nice organic cotton interlock that's very soft and more stable than a jersey.

ReplyDeleteSome experts stitch narrow clear elastic into shoulder seams on knits to give the seam some stability and recovery. I'm thinking you could do the same on the neckline when trimming with woven bias? Would need to test, of course.

ReplyDeleteI actually don't agree that it's not Worth doing t shirts because you can buy them in uniglo. Setting aside the ethical concerns of "Made in China" (and elsewhere!), you've still produced a garment that, though simple, you wouldn't find in Uniglo or any other high street store. You've also used up materials already bought in order to finish it. And I believe that there is a pleasure in knowing that the garment next to your skin has been hand made (especially if it's by yourself or someone your love) - the whole process become human and not just commercial. It's a nice, practical t shirt with an original twist that will get lots of wear - who needs Uniglo?!!

ReplyDeletePeter, your next jersey fabric project, pick up a heavier weight jersey, or even venture into wool jersey, thinking fall 2015. Make yourself a long sleeve jersey top. The project is simple and you can do most of it on the serger. I would also suggest that you make a medium and not something so tight. Remember to:

ReplyDelete1. Stay the shoulder seams with a twill binding, you can do this on the serger and feed the tape as you do the seam.

2. Stay stitch around the neck opening, before you go to attached your collar or binding of some sort.

3. Make sure you serger every flat to avoid sergering in a circle

4. Attach twill tape or binding at the back along the neck line, this will further avoid it being stretched out of shape thru wear and taking the top off and on

5. Finish serging your side seams, then press up your hem

6. In lieu of not having a cover stitch machine, double stitch 2 narrow parallel lines or one on the hems. or use a twin needle that will give you a cover stitch look with stretch, which is what you are looking for with knits. Our jewsewing.com friend also has a technique using elastic tape that you can look at. She made a jersey halston top with the technique

sorry didn't mean jewsewing.com (just got thru passover myself last saturday, so that must be on my mind)

Deletejetsetsewing.com

Organic cottons plus has very nice quality jersey and interlock. You get what you pay for. Sometimes I want cheaper or trendier...then I shop girl charlee.

ReplyDeleteAnother option is to add a strip of fusible interfacing in the seam allowances where the woven fabric meets the knit at the placket and collar.

ReplyDeleteHello,

ReplyDeleteI have come acoss the same challenges. So may be I can help a little bit. Some of the tips have been already mentioned, but I would like to add a little bit here and there:

1) Avoid single knit. It is so thin and is hard to cut out as it rolls up on the edges. Interlock is really the better choice.

2) Add a little bit of spray starch before cutting the fabric.

3) Look for knits with a little spandex. They do not stretch out so much when sewing and later they do not wear out and get back to there original size and form.

3) Stabelize stitches with Tear away or Wash away Stabelizer for the hem and neckline. Fusible interfacing works great around the armhole to prevent stretching when wearing the T. But for the hem and the neckline you would want it to be stiff like a woven when sewing it. Later on you'd rather want the stretching properties back.

4) I also like using a twin needle for the hem to make it look like a cover stitch.

5) Using transparent elastic for shoulder seem is an alternative to twill binding.

Enjoy sewing!

Rubina

Great tips. Thanks, Rubina!

Delete